Both silicone rubber fiberglass sleeves and acrylic fiberglass sleeves start with weaving alkali-free glass fibers into a tubular shape. But then, they go through different processes to coat the outside with different insulating materials. And it's these differences in materials and manufacturing that lead to variations in performance and applications. The two are similar in appearance, both are available in a variety of colors, and can be customized in different sizes, voltage ratings, etc.

So what is the difference between the two?

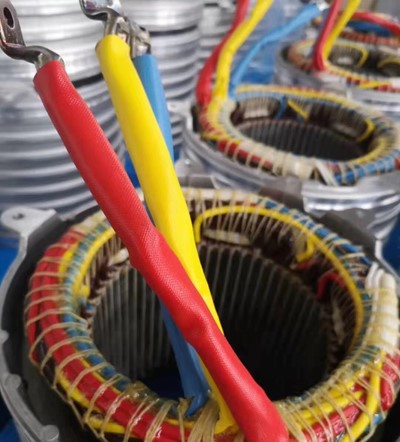

For silicone rubber fiberglass sleeves, there are two forms - inner fiber-outer rubber or inner rubber-outer fiber. The inner fiber-outer rubber type is more common. The process involves first weaving the fibers into a tube, then coating the outside with liquid silicone rubber which is cured at high temps. Depending on the requirements, several coating and curing cycles are required before the final winding into the product.

Silicone rubber fiberglass sleeves are renowned for their high dielectric strength, excellent flexibility, heat aging resistance, flame retardancy, and an operating temperature range from -40°C up to 200°C. This gives them a wider temp range compared to acrylic fiberglass sleeves which is only -30°C to 155°C. They're widely used for circuit insulation in areas like new energy vehicles, specialty vehicles, rail transport, aerospace/military and more.

On the other hand, acrylic fiberglass sleeves are made by coating the outer surface of the woven glass fiber tube with modified acrylic resin, which is then heat-cured to form an insulating varnish tube. This product offers reliable heat resistance, good oil resistance, excellent insulation performance, abrasion resistance, and flexibility too.

In summary, although silicone rubber and acrylic fiberglass tubing look similar, their insulation performance, temperature range, flexibility and other properties, as well as key application areas are slightly different. How to make a choice depends on your actual use scenario. If you need any clarification or have other questions, please let me know! We will explain everything to you.

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com