Maybe you also know that the electronics industry, new energy batteries and electronic control systems have different reference bases and considerations when selecting the thermal conductivity of thermal conductive gap filler gels. The following are some key points for each industry when selecting thermal conductive gap filler gels and their impact on final use.

1. Electronics industry

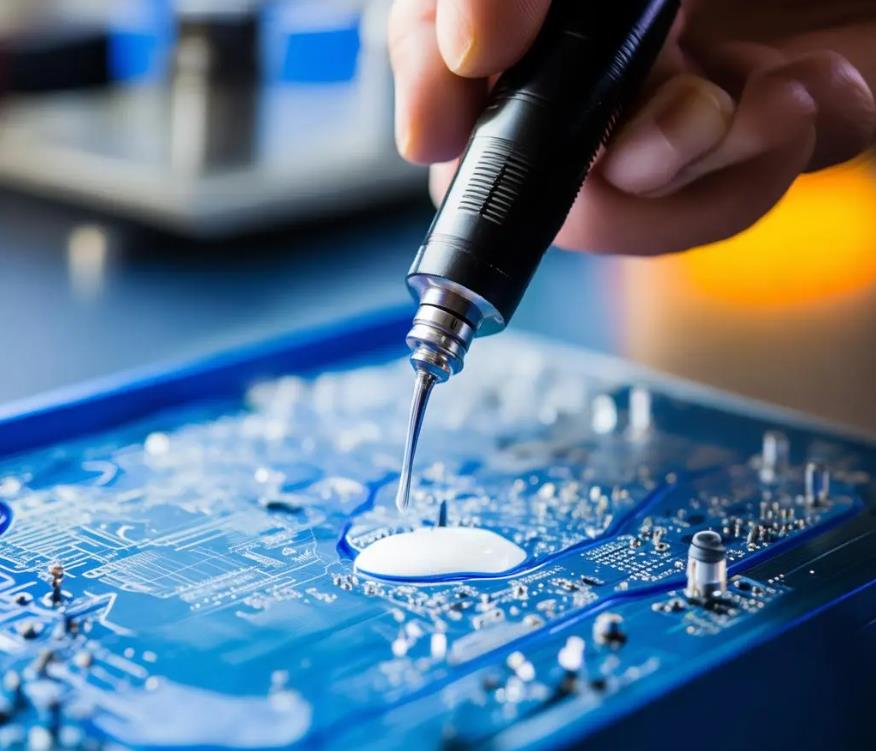

In the electronics industry, the thermal conductivity of thermal conductive gap filler gels usually needs to be selected based on the thermal management requirements of the product. Heat-generating components in electronic devices, such as integrated circuits, power management modules, etc., need to transfer heat quickly to the heat sink or heat sink through thermal conductive gels. The thermal conductivity of thermal conductive products used in the electronics industry is relatively high, and generally thermal conductive gels with a thermal conductivity in the range of 1.0~8.0W/m·K are selected to ensure good heat dissipation.

If the thermal conductivity of the thermal conductive gap filler gel is too low, it will lead to poor heat transfer, causing the electronic equipment to overheat, affecting performance and life. On the contrary, if the thermal conductivity is too high, it will increase costs and cause potential stress on the structure of the electronic equipment.

2. New Energy Batteries

In the new energy battery industry, thermally conductive gap filler gel is mainly used for heat dissipation of battery modules and battery packs to maintain the operating temperature of the battery within an appropriate range. Batteries generate a lot of heat during charging and discharging. Failure to dissipate heat in time may cause battery performance degradation or even safety accidents.

The thermal conductivity of thermally conductive gap filler gel currently used in the battery industry is usually between 1.0-3.0 W/m·K. For batteries with higher energy density, a higher thermal conductivity may be required to meet their heat dissipation needs. If the thermal conductivity of the thermally conductive gel is insufficient, the battery will overheat during operation, affecting performance and life. If the thermal conductivity is too high, it may increase the weight and volume of the battery module and affect the overall design.

3. Electronic Control System

Thermal conductive gap filler gel in the electronic control system is mainly used for heat dissipation and shock absorption. The thermally conductive gap filler gel needs to be able to effectively transfer heat from heat source components (such as power modules, inverters, etc.) to radiators or other heat dissipation structures. The requirements for thermal conductivity of the electronic control system are relatively flexible, and generally a thermally conductive gel with a thermal conductivity of 0.5-4.0 W/m·K is selected. However, the specific selection also needs to consider factors such as the structure, size and weight of the electronic control system.

The VS-GF series of thermal conductive gap fillers developed and produced by Volsun have been used in large quantities in the electronics, battery, electronic control and other industries. We have accumulated a lot of industry experience and can recommend the best product models to customers; The VS-GF series of thermal conductive adhesives developed by Volsun have a full range of specifications and can also be customized according to customer's special requirements.

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com