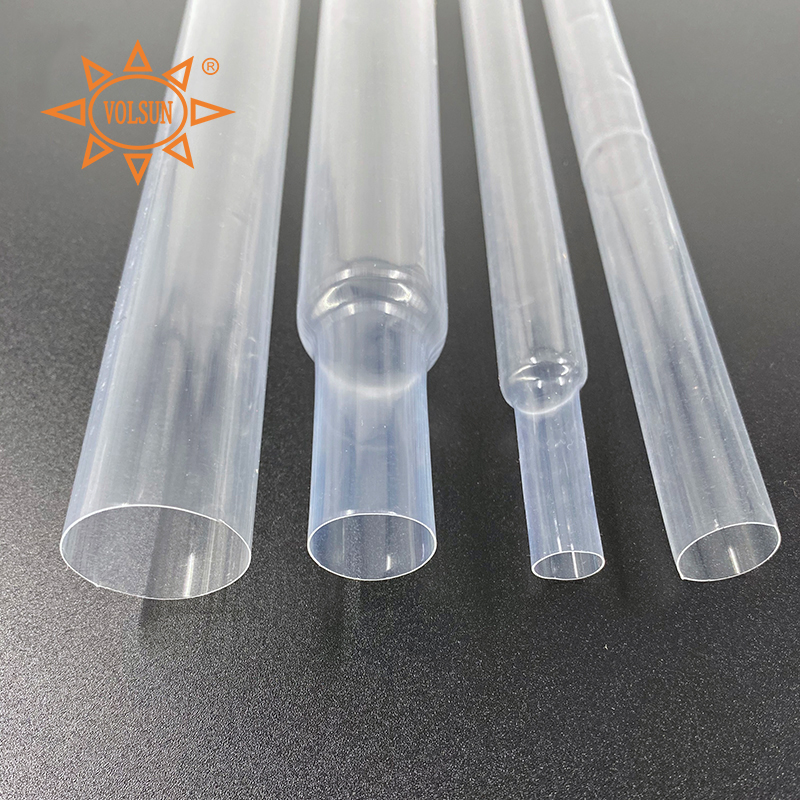

You may know that in the field of protection of wires, cables and various types of pipelines, the FEP heat shrink tubing of Suzhou Volsun Electronic Technology Co., Ltd. has become a leader in the industry with its unique product advantages. As a company focusing on the research and development and production of new materials, its FEP heat shrink tubing has won the trust of the market with its exquisite manufacturing process and strict quality management.

1. Selected FEP materials, excellent performance

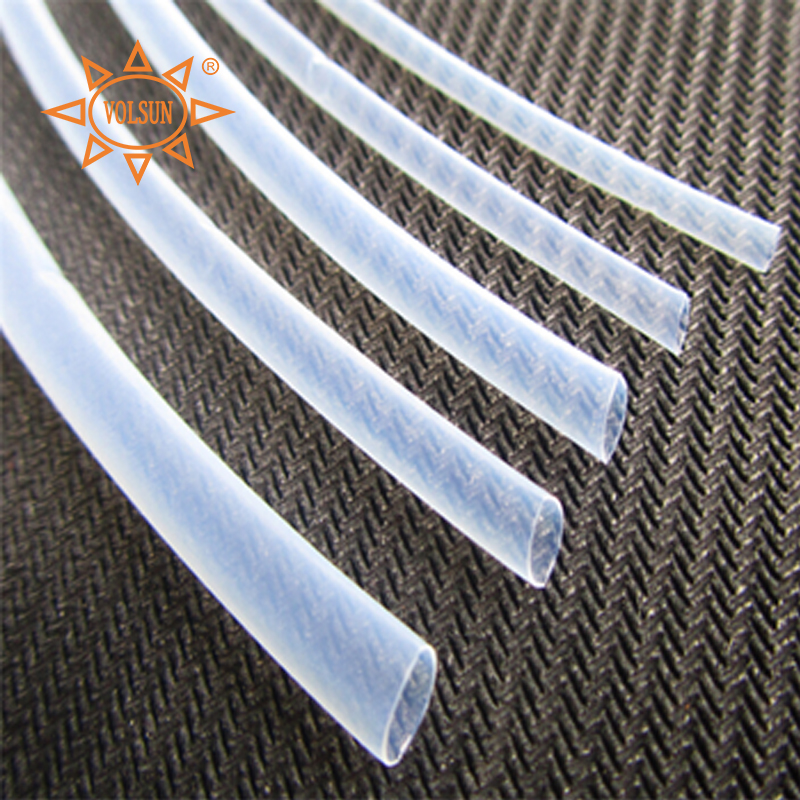

Volsun's FEP heat shrink tubing uses high-quality fluorinated ethylene propylene copolymer (FEP) materials, which have excellent high temperature resistance (long-term 200℃), chemical corrosion resistance, electrical insulation (dielectric strength ≥30kV/mm) and optical transparency. The use of this material ensures the stability and reliability of the product in complex environments.2. Precision manufacturing, precise shrinkage

Volsun has advanced production equipment and a professional technical team to ensure that the FEP heat shrink tubing is accurate in size and stable in shrinkage ratio during the production process, providing customers with an efficient and convenient installation experience.

Five advantages of Volsun FEP heat shrink tubing

1. High temperature resistance

FEP heat shrink tubing can be used for a long time at a temperature of up to 200℃, and the short-term use temperature can reach 260℃, which is suitable for various high temperature environments.

2. Excellent electrical insulation

The product has extremely high insulation resistance and can withstand voltages up to 1500V, effectively ensuring the electrical safety of wires and cables.

3. Chemical corrosion resistance

FEP materials have extremely high resistance to most chemicals and are suitable for the protection of chemical and medical pipelines.

4. Accurate shrinkage ratio

The shrinkage ratio is stable at about 1.5:1, which can fit objects of various shapes tightly to ensure the protective effect.

5. Easy installation

FEP heat shrink tubing can shrink quickly by using an oven for heating; in special cases, a hot air gun can also be used for heating to achieve tight wrapping and save installation time.

Volsun FEP heat shrink tubing has a wide range of applications and is widely used in the following fields:

1. Electronic and electrical industry

It is used for insulation protection of wires, cables and instruments to improve product safety performance and extend service life.

2. Food and Medical

Provide corrosion-resistant and high-temperature-resistant protection for medical pipelines to ensure medical safety.

3. Aerospace

Cable and pipeline protection used in the aerospace field to adapt to harsh working environments.

4. Fiber Optic Communication

Provide precise protection for fiber optic connectors to ensure the stability and reliability of signal transmission.

With the continuous advancement of technology, Volsun will continue to deepen its roots in the field of FEP heat shrink tubing. Its products comply with RoHS standards, are non-toxic and harmless, and provide customers with better products and services.

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com