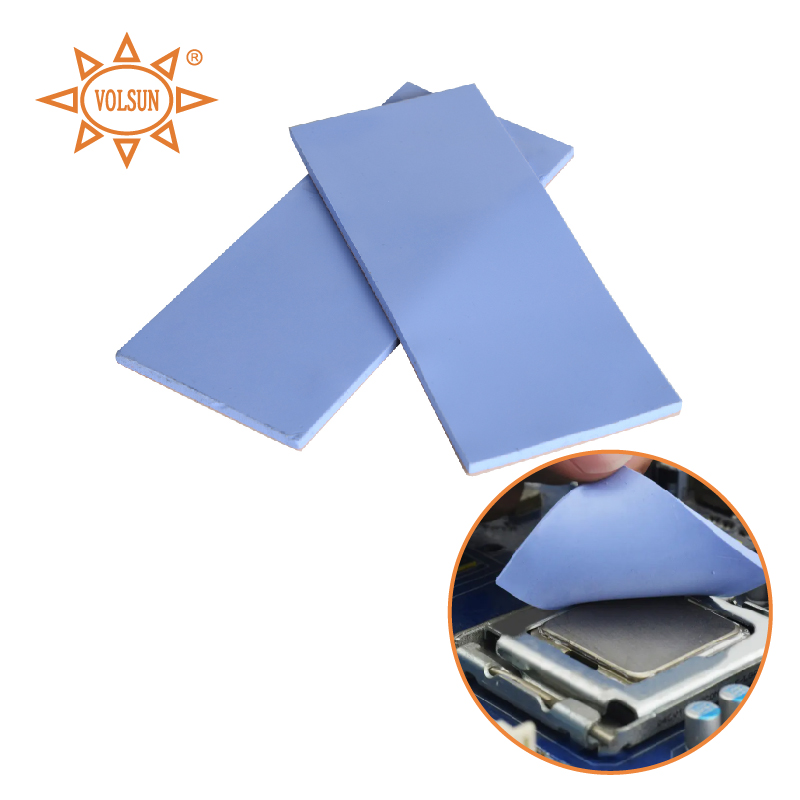

In the heat dissipation solutions of modern electronic devices, silicone thermal pads play a vital role. As a key material to fill the tiny gap between the heating element and the heat sink, the physical properties of the thermal pads directly affect the overall heat dissipation efficiency. Among them, hardness, as a basic physical parameter of the silicone thermal pad, has an important impact on the product performance.

What is hardness of silicone thermal pads?

Hardness is the ability of a material to resist local deformation. For thermal pads, it reflects the hardness and compression performance of the pad. The hardness of the thermal pad directly affects the contact condition between it and the contact surface, thereby affecting the heat conduction efficiency. A thermal pad with too low hardness may not provide enough compression force, resulting in the formation of air bubbles and increasing the contact thermal resistance; while a thermal pad with too high hardness may have difficulty adapting to an uneven contact surface, reducing the contact area, and also affecting heat conduction.

Impact of hardness on thermal conductive performance

The thermal conductive performance of the thermal pad is closely related to its hardness. According to Fourier's law, the heat flux density is proportional to the thermal conductivity, cross-sectional area, temperature difference and material thickness of the material. The hardness of the thermal pad determines its actual thickness after compression in the application, thereby affecting the thermal resistance and heat flux density. Therefore, a thermal pad with moderate hardness can better fill the unevenness of the contact surface, reduce the air gap, and improve the efficiency of heat conduction.

In addition, the thermal pad needs to withstand certain mechanical stress during installation and use. thermal pads with higher hardness have better resistance to compression and deformation, which can improve the mechanical stability of the pad to a certain extent. However, too high hardness may cause the pad to be damaged during installation or difficult to adapt to the contact surface of complex shape. So, how to choose the hardness of the thermal pad?

When selecting a thermal pad, the appropriate hardness should be determined according to the specific application environment and requirements. For example, in a high-performance computing environment that requires rapid heat dissipation, it may be necessary to select a pad with lower hardness and higher compression rate to achieve better heat conduction. In industrial applications with large vibrations, it may be necessary to select a pad with higher hardness and more stable mechanical properties.

In short, the hardness of the silicone thermal pad is one of the key factors to ensure its optimal performance in various applications. Through reasonable hardness design and precise test evaluation, the thermal conductive performance and mechanical stability of the pad can be maximized to meet the heat dissipation needs of different electronic devices. With the trend of electronic equipment towards higher performance, the hardness control of thermal pads will also become more important.

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com