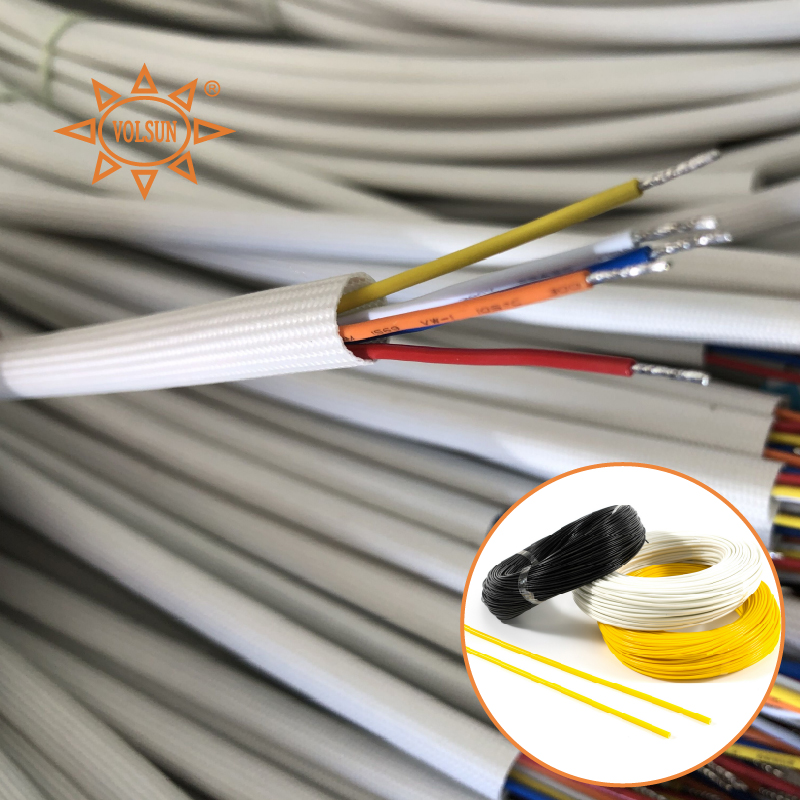

In the wave of the new energy revolution, efficient, safe and reliable insulation materials have become the key to promoting industrial development. Volsun focuses on the research and development and production of glass fiber sleeve in the field of new energy. With its excellent performance and environmental protection characteristics, it has become a trusted partner of the new energy industry and an exclusive guardian in the field of new energy.

The fiberglass sleeves produced by Volsun are widely used, and are mainly used in the following industries in the field of new energy.

1. Electric vehicle industry: The operation of electric vehicles depends on efficient motors and precisely controlled high-voltage systems. Volsun glass fiber sleeves provide excellent insulation protection for electric vehicle motors and high-voltage wiring harnesses.

The glass fiber sleeve is wrapped around the motor windings to provide a high level of electrical insulation to prevent electromagnetic interference, while being resistant to high temperatures to ensure that the motor maintains stable performance at high speeds. In addition, on the high-voltage wiring harness of electric vehicles, the fiberglass sleeve can withstand voltage fluctuations and mechanical shocks, ensuring that the wiring harness is not damaged in the complex in-vehicle environment and ensuring the safe operation of the vehicle.

2. Wind power generation industry: We all know that wind turbines operate in harsh natural environments and have extremely high requirements for material performance. Fiberglass sleeves are used as the insulation layer of generator coils, which can withstand high-frequency vibrations and extreme temperature changes, ensuring that the coils will not short-circuit or be damaged during long-term operation. In the cable connection part of the wind turbine, the glass fiber sleeve provides a solid protective layer to prevent the cable from being damaged by external factors such as wind, sand, and moisture.

3. Solar photovoltaic industry: The stability and safety of solar photovoltaic systems are crucial. Volsun fiberglass sleevings are mainly used for insulation protection of junction boxes and components in solar photovoltaics. Inside the photovoltaic junction box, the glass fiber sleeving is used to isolate the wires and terminals to prevent short circuits caused by heat accumulation or environmental factors, and improve the reliability of the system. In the connection part of the photovoltaic module, the glass fiber sleeve can protect the wires from ultraviolet rays and extreme climates, extending the service life of the module.

We know that in the energy storage industry, the battery pack is the core of the energy storage system, and has extremely high requirements for safety and durability. Inside the battery pack, the glass fiber sleeve is used to isolate the battery cells to prevent short circuits between batteries. At the same time, it is resistant to high temperatures and adapts to the high temperature environment generated by the battery during charging and discharging. On the line connecting the battery pack to the external equipment, the glass fiber sleeve provides a layer of high temperature resistance and insulation protection to ensure that the connection line remains stable in a complex working environment.

The glass fiber sleeve produced by Volsun is safe and environmentally friendly, complies with UL certificate, RoHS & REACH standards, and strictly follows the ISO9001 quality management system to ensure that every meter of the tube meets high standards. Specially formulated silicone resin is used to enhance the heat resistance and mechanical properties of the glass fiber sleeve. Through precision weaving and high temperature treatment, the glass fiber sleeve structure is dense and the performance is stable. It can work for a long time at a high temperature of 200°C, and can adapt well to the high temperature environment of new energy equipment, becoming the backbone of promoting the development of the new energy industry.

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com