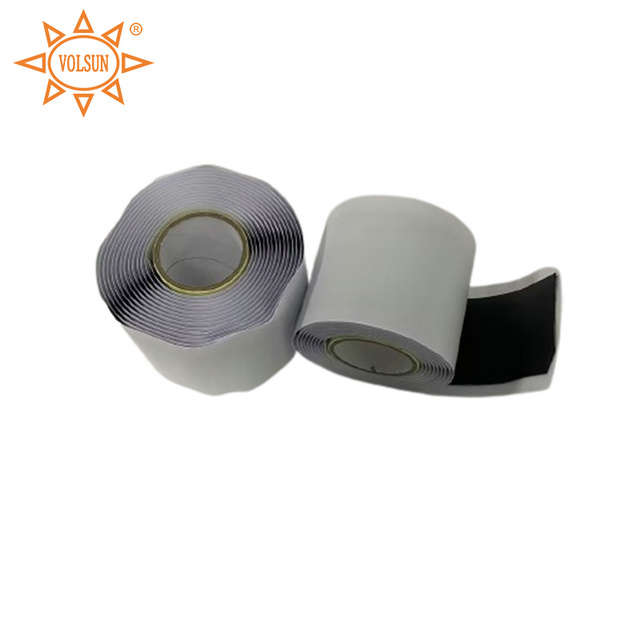

Volsun Insulated Waterseal Mastic Tape Butyl Rubber Waterproof Mastic Tape

Description

Volsun Waterproof insulation tape is mainly composed of synthetic rubber, which can be used as the connecting insulation material of electrical conductors at 80℃. It has good water resistance, suitable for low-voltage wire insulation, handling abnormal conditions in the connection, moisture-proof sealing of the ground wire of the high-voltage joint, wrapping and covering of the surface of the winding high-voltage line and irregular joints or valve joints.

Features

- Operating temperature:-40℃~+85℃

- Non-corrosive adhesive in the form of flexible tape, clean to use, no waste

- Provides optimal compliance to help seal multi-conductor cable connections and wire outlets at high voltage contacts

- Sealing grade:IP68

Technical Performance

Technical specification of waterproof insulating composite tape backing

| Item | Typical Data | Test Method |

| Tensile strength | ≥1.7MPa | GB/T 528-2009 |

| Breakdown strength | ≥20kV/mm | GB/T1698-2005 |

| Volume resistivity | ≥1*1014Ω*cm | JB/T 1692-2008 |

Technical specification of waterproof insulation tape

| Item | Typical Data | Test Method |

| Tensile strength | ≥1.0MPa | GB/T 528-2009 |

| Elongation at break | ≥500% | GB/T 528-2009 |

| Heat Resistance(100℃,1h) | No Crack | JB/T 6464-2006 |

|

Resistant to thermal stress cracking(130℃,1h) |

No Crack | JB/T 6464-2006 |

| Adhesion (with stainless steel plate,N/cm) | ≥26 | GB/T2792-2014 |

|

Water absorption(23℃, 24h,%) |

≤0.15 | GB/T 1034-2008 |

| Size(mm) | Width(mm) | Thickness(mm) | Length(m) |

| VS-T1 | 50.0±1.5 | 1.65±0.1 | 3.0±0.1 |

Usage Method & Precautions

- Clean the surface of the substrate to be installed before use

- Cut the product size based on the dimensions of the installation position

- The environment should be free of large debris or other pollutants to avoid affecting the installation effect

- The cutting size of the product should be similar to that of the installation position. The deviation should not

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com