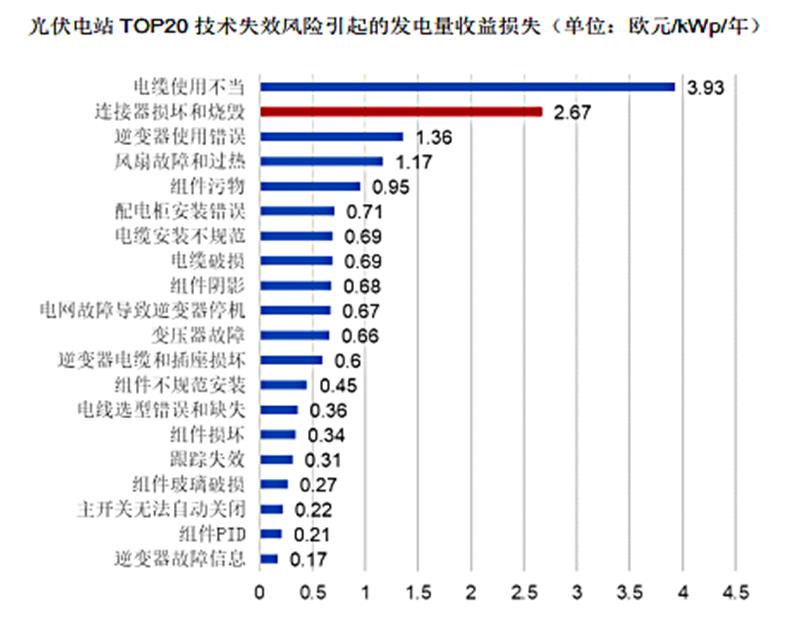

In the field of photovoltaic power generation, photovoltaic connectors serve as a bridge connecting key equipment such as photovoltaic modules, combiner boxes, controllers, and inverters. The excellence of their performance is directly related to the operational efficiency and safety of the entire photovoltaic power station. However, according to an authoritative report released by the "Solar Bankability" project team of the European Union's Horizon2020 program, the risk of damage and burnout of photovoltaic connectors ranks second among the TOP20 technical failure risks of power stations. This data undoubtedly highlights the urgency for in-depth analysis and optimization of these critical components.

Key Performance Requirements for Photovoltaic Connectors

1.Conductive properties: Photovoltaic connectors must have excellent electrical conductivity to ensure that the contact resistance is maintained below 0.35 milliohms to reduce energy loss and improve system energy efficiency.

2. Safety performance: Since solar equipment is often exposed to changing outdoor environments, photovoltaic connectors must have properties such as waterproofing, high temperature resistance, UV resistance, corrosion resistance and high insulation. The protection level needs to reach IP68 standard to adapt to extreme weather conditions.

3. Structural stability: Connectors need to be designed to ensure their robustness and reliability during connection. For example, when the MC4 connector carries 39 amps of current, its operating temperature should be controlled below 105 degrees Celsius to ensure long-term stable operation.

Solutions for Photovoltaic Connector Failure

In the face of photovoltaic connector failure, Suzhou Volsun Electronic Technology Co., Ltd., with its keen market insights and extensive technical expertise, has introduced the RUBLS-SILIC high-rate silicone rubber cold shrink tube, providing a comprehensive protection solution for photovoltaic connectors.

The Advantages of Volsun High Shrink Ratio Silicone Cold Shrink Tubing

1. Temperature resistance range: Made of high-quality silicone rubber material, it can be used continuously in a wide temperature range from -60°C to 200°C, ensuring reliability under extreme climate conditions.

2. Expansion rate: The expansion ratio is about 6 times, adapting to the connection sealing of different diameters, ensuring the sealing and waterproof and moisture-proof performance of the connection point.

3. Weather resistance: After 1,000 hours of UV irradiation, there are no cracks on the surface. After another 72 hours of salt spray corrosion resistance test, the protected metal is observed to be free of rust, showing excellent weather resistance and corrosion resistance.

4. Physical and mechanical properties: The tear resistance is high, measured at about 36kN/mm, ensuring the stability and durability of the material when encountering external forces.

5. Easy to install: There is no need to heat or use special tools, and the installation can be completed by simply pulling out the support strips, which greatly simplifies the construction process and saves time and labor.

In conclusion, Volsun's RUBLS-SILIC high shrink ratio silicone rubber cold shrink tube, with its excellent high temperature resistance, weather resistance, physical and mechanical properties and simple installation process, has become an ideal choice for protecting various connectors and cables in photovoltaic power plants. Whether in harsh desert environments, humid coastal areas, or high mountain areas with extreme temperature differences, this cold shrink tube can provide a solid guarantee for the stable operation of photovoltaic systems. Volsun is committed to providing high-performance and reliable products. Choosing Volsun means choosing a trustworthy long-term partner, providing a solid guarantee for the safe and stable operation of your photovoltaic power station.

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com