Thermally conductive silicone pads and thermally conductive gap fillers are commonly used in various applications to improve thermal conductivity. However, they have different characteristics and are suitable for different scenarios. So, how do you choose the right one for your specific application?

Let's look at the key differences between them.

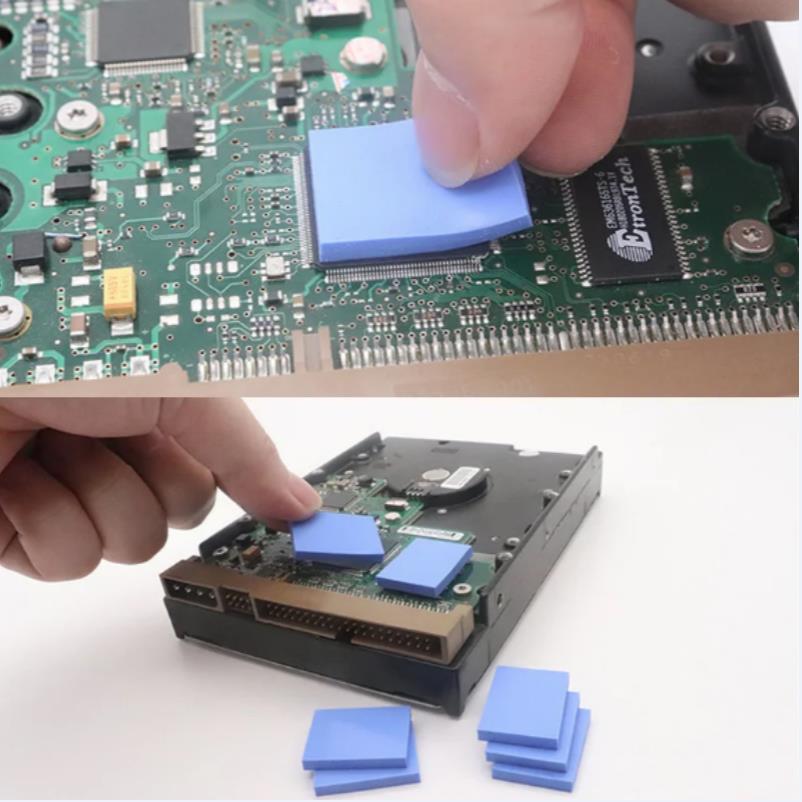

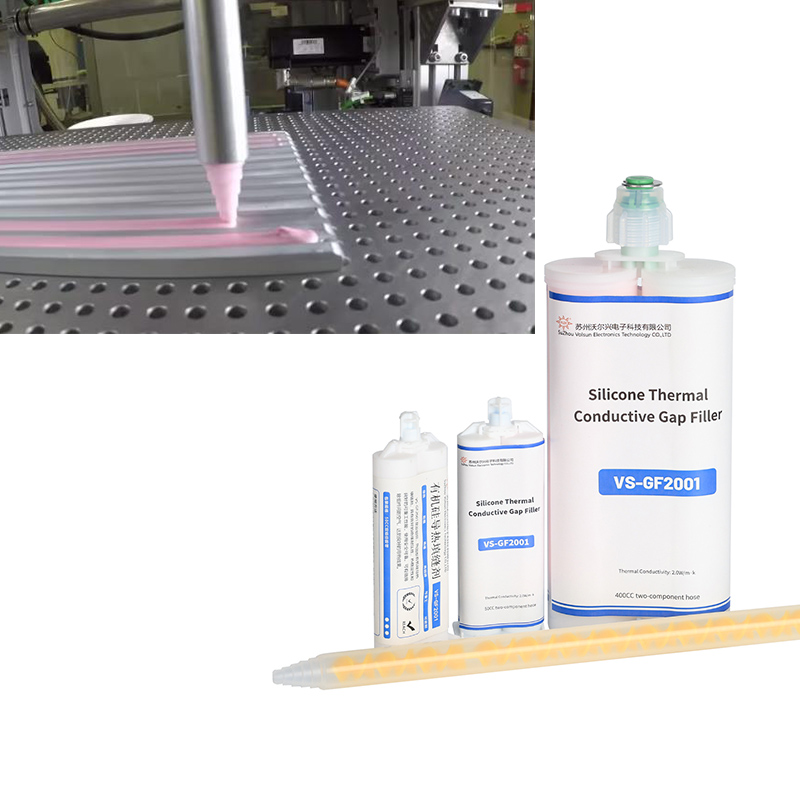

Physical Form: Silicone thermal pads are solid and soft, while thermally conductive gap fillers are liquid or gel-like with good flowability.

Thermal Conductivity: Silicone thermal pads have a thermal conductivity ranging from 0.8W/M·K to 8.0W/M·K, whereas thermally conductive gap fillers typically have a thermal conductivity above 2.0W/M·K. The fluidity of gap fillers allows them to fill gaps more effectively, reducing interface thermal resistance and improving thermal conductivity.

Insulation Properties: Silicone pads offer good insulation, preventing short circuits or leakage in electronic devices. Thermally conductive gap fillers also provide insulation, but the level of insulation depends on the type and formulation of the product.

Usage and installation: Thermally conductive silicone pads are solid and can be cut into shapes for easy installation and maintenance. On the other hand, thermal conductive gap fillers need dispensing equipment for application and are ideal for automated production.

Longevity and reusability: Thermally conductive pads have a long lifespan and can be reused, making them suitable for scenarios that require frequent maintenance. Once cured, thermal conductive gap fillers are not reworkable and are best for long-term fixed use environments.

In conclusion, the choice between thermally conductive silicone pads and thermal conductive gap fillers should be based on specific application needs, cost considerations, and ease of use. For rapid heat dissipation, automated production, or one-time use, thermal conductive gap fillers may be preferred. For reusable, easy-to-cut, or specific shape requirements, thermally conductive silicone pads are a better option.

Welcome to contact us if any needs!

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com