In the rapidly developing industrial field, the choice of materials often determines the performance and application range of the product. In recent years, a new type of sleeve, fiberglass sleeve (also known as glass fiber sleeve), has gradually become a leader in modern industrial materials due to its excellent performance and wide application prospects. So, what are the material composition and characteristics of glass fiber sleeve?

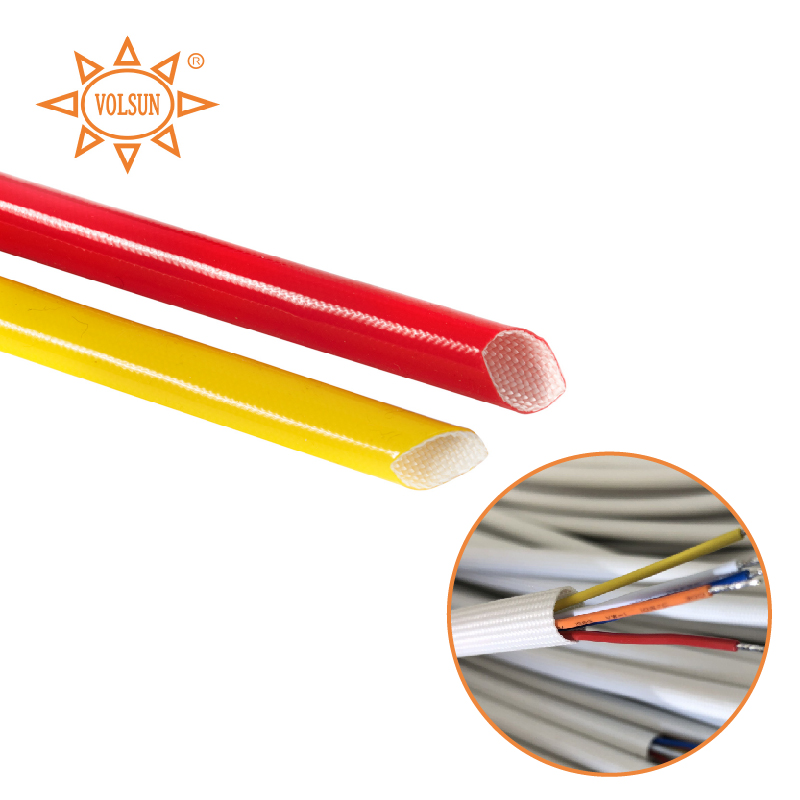

Glass fiber sleeve is a sleeve tube made of glass fiber and resin as the main raw materials. It is made by weaving alkali-free glass fiber into a tube through a special production process, coating silicone rubber on the outer layer of the tube, and then curing it. These processes not only ensure the high strength and lightness of the glass fiber sleeve, but also give it a series of other excellent properties.

Heat resistance: It can be used in a wide temperature range. Glass fiber sleeves with special resin formulas can even withstand high temperatures above 200°C.

Lightweight and high strength: Compared with traditional materials such as carbon steel, glass fiber sleeves have lower density while maintaining high strength, which greatly reduces their own weight.

Insulation performance: As a non-conductor, glass fiber sleeves have excellent electrical and thermal insulation performance and are suitable for dense areas of power transmission and telecommunication lines.

Wear resistance: The inner wall of the glass fiber sleeve is smooth, with low friction resistance, which effectively extends the service life of the fiberglass sleeves.

What are the types of glass fiber sleeves?

According to the different outer tube coating materials, there are mainly silicone rubber coated glass fiber sleeves, acrylic coated glass fiber sleeves, and PVC glass fiber sleeves.

Application fields of glass fiber sleeve

With the above characteristics, glass fiber sleeve plays an important role in many industries and is widely used in insulation protection of circuit harnesses such as new energy vehicles, special vehicles, rail transportation, military and aerospace, etc.

As a new type of composite material sleeve, the unique performance and wide application range of glass fiber sleeve have brought revolutionary changes to modern industry. With the advancement of science and technology and the growth of industrial demand, the development prospects of glass fiber sleeve are very broad. As a professional manufacturer, the glass fiber sleeve produced by Volsun has excellent performance, complies with RoHS, REACH, and has passed UL certification. In the field of green building and new energy, Volsun glass fiber sleeve has provided strong support for building energy conservation and sustainable development with its light weight, high strength and good environmental adaptability, and has been recognized and praised by customers.

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com