Electrocorrosion is a common problem currently faced in new energy vehicle electric drives, wind turbine generators, rail transit, marine propulsion, and industrial motors. This isn't a new issue, and earlier efforts to mitigate it were possible through optimization of carbon brushes, control strategies, or mechanical structures. However, with new energy vehicle electric drives advancing to 800V, the widespread use of silicon carbide controllers, and motor speeds exceeding 20,000 rpm, traditional suppression and mitigation methods are no longer sufficient to meet the evolving needs of the industry. To address this pain point, a shaft grounding ring based on flexible contact technology has become a widely adopted solution.

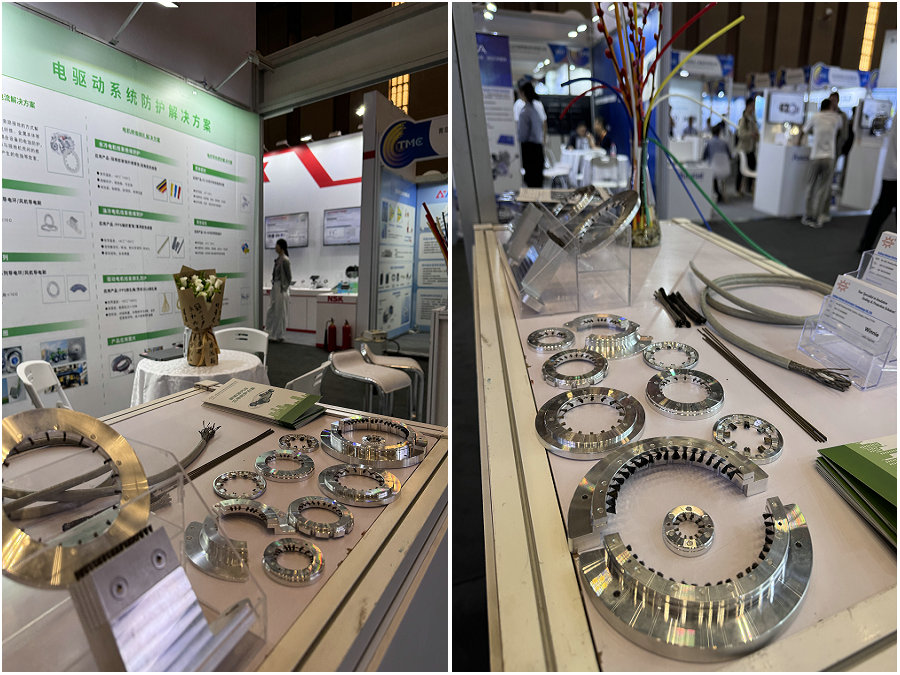

Volsun shaft grounding rings/conductive brushes are primarily composed of conductive fibers and a metal body, offering lightweight, low resistance, and physically stable current transmission. Their cantilevered design allows the brush tip to conform to the shaft surface, resulting in high conductivity and wear resistance, as well as low friction and noise during operation.

Volsun's shaft grounding ring products are currently divided into three main categories based on application scenarios and testing requirements:

- The first is the RD/RDW/ST/STW series of conductive rings, available in full, semi-circular, and fan-shaped configurations. They are suitable for new energy vehicle motors, rail transit, and industrial motors, supporting various mounting methods such as bolts and press-fit.

- The second is the TDB series of conductive brushes, primarily for wind turbine motors, industrial motors, and rail traction motors, primarily using bolts for mounting.

- The third is the TF series of test accessories, includes test rings, test pens, and conductive holders, fully supporting various shaft electrical testing needs.

Furthermore, as market demand evolves, Volsun is committed to continuous product innovation. The shaft grounding ring has now reached its third generation. This third-generation shaft grounding ring consists of two components: a customized metal ring body and a relatively standardized conductive fiber module. The most significant upgrade to the third generation is the prefabricated fiber module, which is laser-welded to the metal ring for high precision and strength.

This approach offers four key advantages:

- Volsun's metal-based carbon fiber core materials and processes are centrally optimized and rigorously controlled.

- The ring structure is simplified, with fewer parts and streamlined processes, significantly reducing manual pre-assembly time.

- Overall costs are significantly reduced, exceeding 20% lower than comparable products in the industry.

- Modularization allows for enhanced automated production capabilities while maintaining the reliability of previous generations, enabling better response to customer needs for varying batch sizes.

Up to now, Volsun has established deep partnerships with over 70% of mainstream domestic automakers, encompassing both traditional brands and emerging car manufacturers. We are proud to maintain a zero-quality record for all our delivered conductive rings, demonstrating their proven reliability and durability. To meet continued demand, we are currently constructing our sixth and seventh automated production lines, further ensuring a stable and efficient supply chain for our customers.

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com