6w/m.k Factory Customized Soft Silicone Material thermal Conductivity Pads

Description

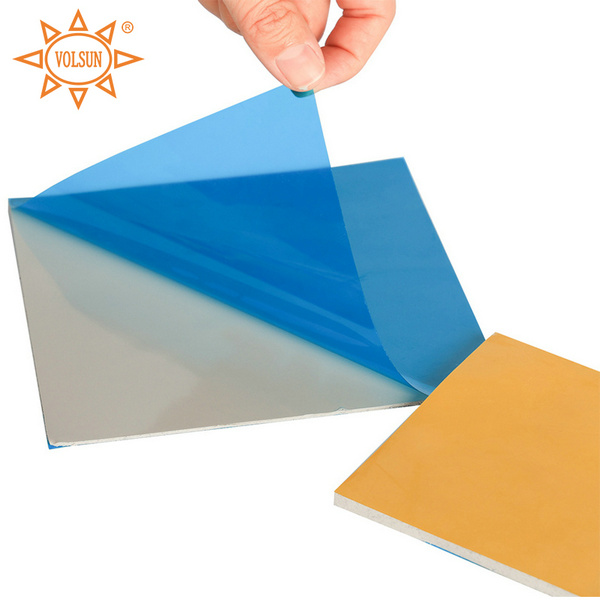

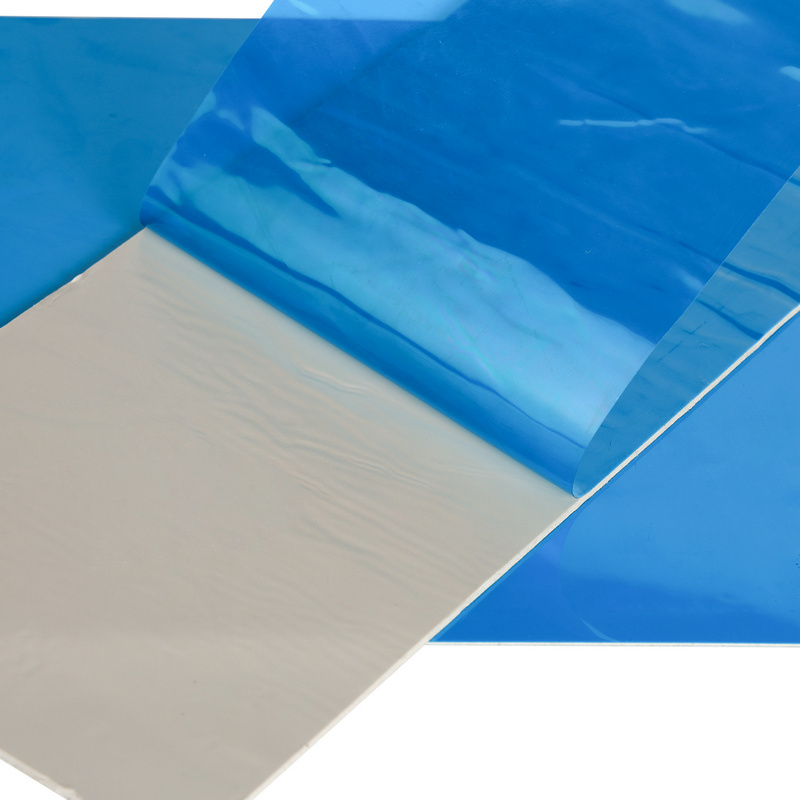

Volsun VS-GP6001 Silicone thermal pads achieve low interfacial thermal resistance at relatively low pressures, with excellent thermal conductivity, thermal stability, flexibility and resilience, safe and reliable use. Applied between the power device and the cooling aluminum sheet or the machine shell, the air can be effectively excluded to achieve good thermal conductivity filling effect.

Features

-

Operating temperature: -40℃~+200℃

-

High thermal conductivity, low thermal resistance

-

Excellent surface wettability and resilience

-

Excellent flame retardancy

-

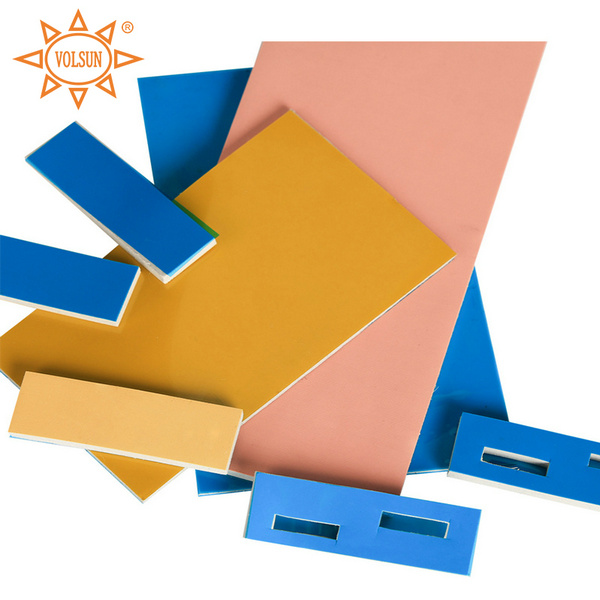

Multiple thickness selection, wide application range

-

Environmental protection standards: RoHS, REACH

Technical Performance

| Item | Typical value | Test method |

| color | Gary | Visual inspection |

| Density (g/cm3) | 3.4 | ASTM D792 |

| Thickness (mm) | 0.5~5.0 | ASTM D374 |

| Hardness (Shore OO) | 45-70 | GB/T 531.1-2008 |

| Tensile strength (KPa) | ≥80 | GB/T 528-2009 |

| Elongation at break (%) | ≥10 | GB/T 528-2009 |

| Thermal conductivity (W/m·k) | 6.0 | ASTM D5470 |

| Flame Rating | V-0 | UL94 |

| Dielectric Breakdown Voltage (kV) | >6 | ASTM D149 |

| Volume resistivity | ≥1.0×10 12 | ASTM D257 |

How to Apply Thermally Conductive Silicone Pads?

- Clean the surface of the substrate to be installed before use

- Select products with corresponding specifications based on the dimensions of the installation parts

- The environment should be free of large debris or other pollutants to avoid affecting the installation effect and protective performance of the materials

- The specifications of the product should be similar to the dimensions of the installation site. The deviation should not be too large

Storage conditions & shelf life

- Temperature: 20℃<T<30℃

- Relative humidity: RH<80%

- Shelf life: 12 months from the production date

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com