1.5kv/2.5kv/4kv/7kv Fiberglass Wire Sleeve Silicone Resin Fiberglass Sleeving Manufacturer

Description

Silicone rubber coated fiberglass sleeving is made of alkali-free fiberglass woven into a tube, coated with a layer of silicone rubber composite material on the outer layer of the tube, and then heated and cured. With high dielectric strength, good flexibility, heat resistance aging, flame retardant, temperature resistance up to 200℃. Widely used in household electrical appliances, motors, electromechanical equipment, vehicles, rail transit, aerospace and other circuit insulation protection.

Features

Technical Performance

Structure

Dimensions

Note: Non-standard dimensions, different cutting lengths and packages also available on your request.

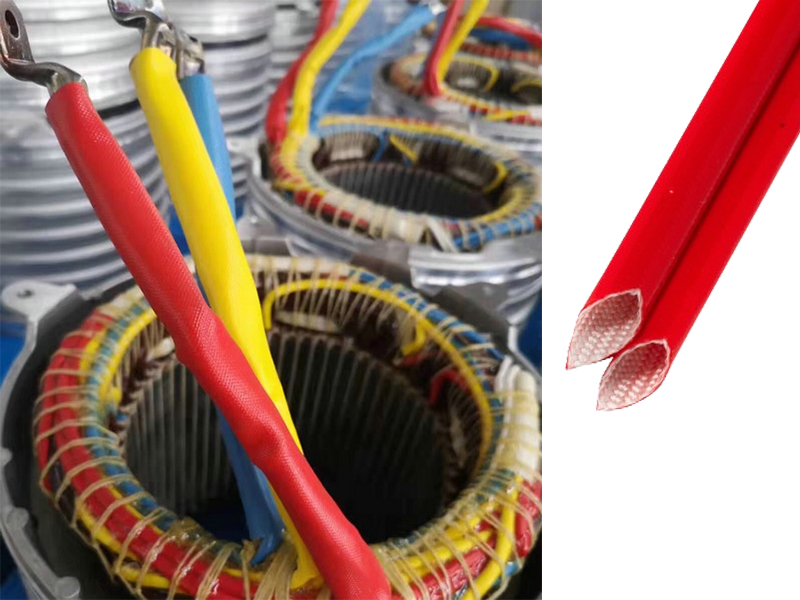

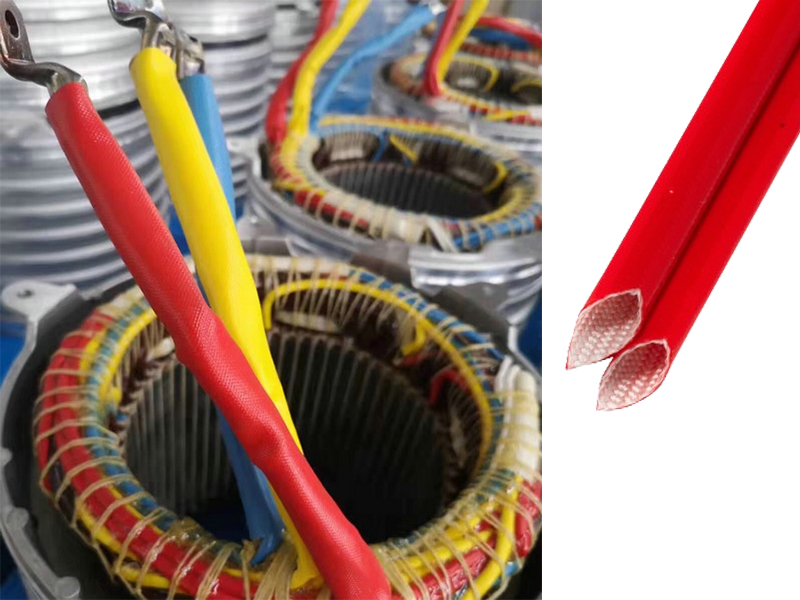

Typical Applications

Silicone fiberglass sleeves that are used for motor's wire harness insualtion protection.

Frequently Asked Questions

Q1: What are the key performance of the silicone coated glass fiber sleeve?

A: The Silicone coated fiberglass sleeve boasts high dielectric strength, excellent softness, heat aging resistance, oil resistance, flame retardancy, and a remarkable temperature resistance of up to 200°C.

Q2: In which industries or applications can the silicone rubber fiberglass sleeve be used?

A: The Silicone rubber fiberglass sleeve finds wide-ranging utility across industries such as new energy vehicles, special vehicles, rail transit, military, and aerospace.

Q3: What is the quality assurance of the silicone coated braided fiberglass sleeving?

A: We have achieved certifications such as IATF 16949, ISO 9001, and other quality standards.

Our silicone fiberglass sleeving is manufactured using high-quality alkali-free glass fiber and premium-grade silicone rubber and have been approved by UL, RoHS, REACH, etc.

Q4: What is the typical lead time of silicone rubber fiberglass sleeve?

A: For regular sizes that in stock, the lead time usually is 3~5 days around. Please confirm to our sales team for special sizes or requirements.

Q5: Can the silicone coated glass fiber sleeve be customized to specific requirements?

A: Yes, we can produce fiberglass sleeves according to your exact customized requirements.

- Operating temperature:-40°C~200°C

- UL approved

- RoHS, REACH compliant

- Standard colors: transparent ,white, red, yellow, blue, green, black, orange, other colors on request.

Technical Performance

| Properties | Typical Data | Test method |

| Appearance | No leakage, cracking,etc | GB/T 7113.1-2014 |

| Hydrolysis of coating | No coating displacement, adhesion,etc | GB/T 7113.2-2014 |

| Cold bending | -40℃, 4h, no cracks, coating peeling and delamination | IEC60684 |

| Flame retardant | HB | UL94 |

| Breakdown voltage | Reference standards | GB/T 7113.2-2014 |

| Tear strength | ≥50N/mm | / |

Structure

Dimensions

| Size( mm ) | Wall thickness W(mm) | Standard Packing | ||||

|

Diameter (mm) |

Tolerance (mm) |

1500V | 2500V | 4000V | 7000V | m/ea |

| Φ2.0 | -0.10~0.30 | 0.35±0.10 | 0.40±0.10 | 0.45±0.10 | 0.50±0.10 | 100 |

| Φ2.5 | -0.10~0.30 | 0.35±0.10 | 0.40±0.10 | 0.45±0.10 | 0.50±0.10 | 100 |

| Φ3.0 | -0.10~0.30 | 0.35±0.10 | 0.40±0.10 | 0.45±0.10 | 0.50±0.10 | 100 |

| Φ3.5 | -0.10~0.40 | 0.40±0.10 | 0.45±0.10 | 0.50±0.10 | 0.55±0.10 | 100 |

| Φ4.0 | -0.10~0.40 | 0.40±0.10 | 0.45±0.10 | 0.50±0.10 | 0.55±0.10 | 100 |

| Φ4.5 | -0.10~0.40 | 0.40±0.10 | 0.45±0.10 | 0.50±0.10 | 0.55±0.10 | 100 |

| Φ5.0 | -0.10~0.40 | 0.40±0.10 | 0.45±0.10 | 0.50±0.10 | 0.55±0.10 | 100 |

| Φ5.5 | -0.10~0.40 | 0.45±0.10 | 0.50±0.10 | 0.55±0.10 | 0.60±0.10 | 100 |

| Φ6.0 | -0.10~0.40 | 0.45±0.10 | 0.50±0.10 | 0.55±0.10 | 0.60±0.10 | 100 |

| Φ7.0 | -0.10~0.50 | 0.45±0.10 | 0.50±0.10 | 0.55±0.10 | 0.60±0.10 | 100 |

| Φ8.0 | -0.10~0.50 | 0.45±0.10 | 0.50±0.10 | 0.55±0.10 | 0.65±0.10 | 50 |

| Φ9.0 | -0.10~0.50 | 0.45±0.10 | 0.50±0.10 | 0.55±0.10 | 0.65±0.10 | 50 |

| Φ10.0 | -0.20~0.70 | 0.50±0.15 | 0.55±0.15 | 0.65±0.15 | 0.70±0.15 | 50 |

| Φ11.0 | -0.20~0.70 | 0.50±0.15 | 0.55±0.15 | 0.65±0.15 | 0.70±0.15 | 50 |

| Φ12.0 | -0.20~0.70 | 0.50±0.15 | 0.55±0.15 | 0.65±0.15 | 0.70±0.15 | 50 |

| Φ13.0 | -0.30~0.80 | 0.55±0.15 | 0.60±0.15 | 0.70±0.15 | 0.75±0.15 | 50 |

| Φ14.0 | -0.30~0.80 | 0.55±0.15 | 0.60±0.15 | 0.70±0.15 | 0.75±0.15 | 50 |

| Φ15.0 | -0.30~0.80 | 0.55±0.15 | 0.60±0.15 | 0.70±0.15 | 0.75±0.15 | 50 |

| Φ16.0 | -0.30~0.80 | 0.55±0.15 | 0.60±0.15 | 0.70±0.15 | 0.75±0.15 | 50 |

| Φ17.0 | -0.50~1.00 | 0.60±0.20 | 0.60±0.20 | 0.75±0.20 | 0.80±0.20 | 30 |

| Φ18.0 | -0.50~1.00 | 0.60±0.20 | 0.65±0.20 | 0.75±0.20 | 0.80±0.20 | 30 |

| Φ19.0 | -0.50~1.00 | 0.60±0.20 | 0.65±0.20 | 0.80±0.20 | 0.85±0.20 | 30 |

| Φ20.0 | -0.50~1.00 | 0.60±0.20 | 0.65±0.20 | 0.80±0.20 | 0.85±0.20 | 30 |

| Φ22.0 | -0.50~1.00 | 0.65±0.20 | 0.75±0.20 | 0.85±0.20 | 0.90±0.20 | 30 |

| Φ25.0 | -0.50~1.00 | 0.75±0.20 | 0.85±0.20 | 0.95±0.20 | 1.05±0.20 | 30 |

Note: Non-standard dimensions, different cutting lengths and packages also available on your request.

Typical Applications

Silicone fiberglass sleeves that are used for motor's wire harness insualtion protection.

Frequently Asked Questions

Q1: What are the key performance of the silicone coated glass fiber sleeve?

A: The Silicone coated fiberglass sleeve boasts high dielectric strength, excellent softness, heat aging resistance, oil resistance, flame retardancy, and a remarkable temperature resistance of up to 200°C.

Q2: In which industries or applications can the silicone rubber fiberglass sleeve be used?

A: The Silicone rubber fiberglass sleeve finds wide-ranging utility across industries such as new energy vehicles, special vehicles, rail transit, military, and aerospace.

Q3: What is the quality assurance of the silicone coated braided fiberglass sleeving?

A: We have achieved certifications such as IATF 16949, ISO 9001, and other quality standards.

Our silicone fiberglass sleeving is manufactured using high-quality alkali-free glass fiber and premium-grade silicone rubber and have been approved by UL, RoHS, REACH, etc.

Q4: What is the typical lead time of silicone rubber fiberglass sleeve?

A: For regular sizes that in stock, the lead time usually is 3~5 days around. Please confirm to our sales team for special sizes or requirements.

Q5: Can the silicone coated glass fiber sleeve be customized to specific requirements?

A: Yes, we can produce fiberglass sleeves according to your exact customized requirements.

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com